BEHCO | Leading Distributor and Integrator of Pneumatic, Hydraulic, Lubrication, and Motion Control Components and Custom Engineered Systems

DYNAMIC AUTOMATION EXPERIENCE

Representing a wide array of manufacturers

Your Partner for Motion Control, Fluid Power, and Automation.

BEHCO brings over 50 years of dynamic experience to the pneumatic, hydraulic, electro-mechanical, and collaborative robotic automation industry. We are the ideal partner for your motion control, fluid control, and automation requirements since we are an industry-leading stocking distributor of component manufacturers coupled with comprehensive application engineering and manufacturing capabilities. Driven by our customer first attitude, the BEHCO culture has allowed us to forge decades-long partnerships. We don’t settle for less and we never ask our customer-partners to either.

Shop our component manufacturers.

Shipped directly to you!

Behco Solutions

Engineered Systems & Services

At BEHCO, we’re dedicated to providing a higher level of reliability and performance so we can help our customers achieve optimum efficiency with valuable solutions that meet their application’s requirements. Our extensive application knowledge and industry expertise allows us to identify opportunities and the deliver resolution across a variety of robotic, pneumatic, hydraulic, and motion control applications and systems.

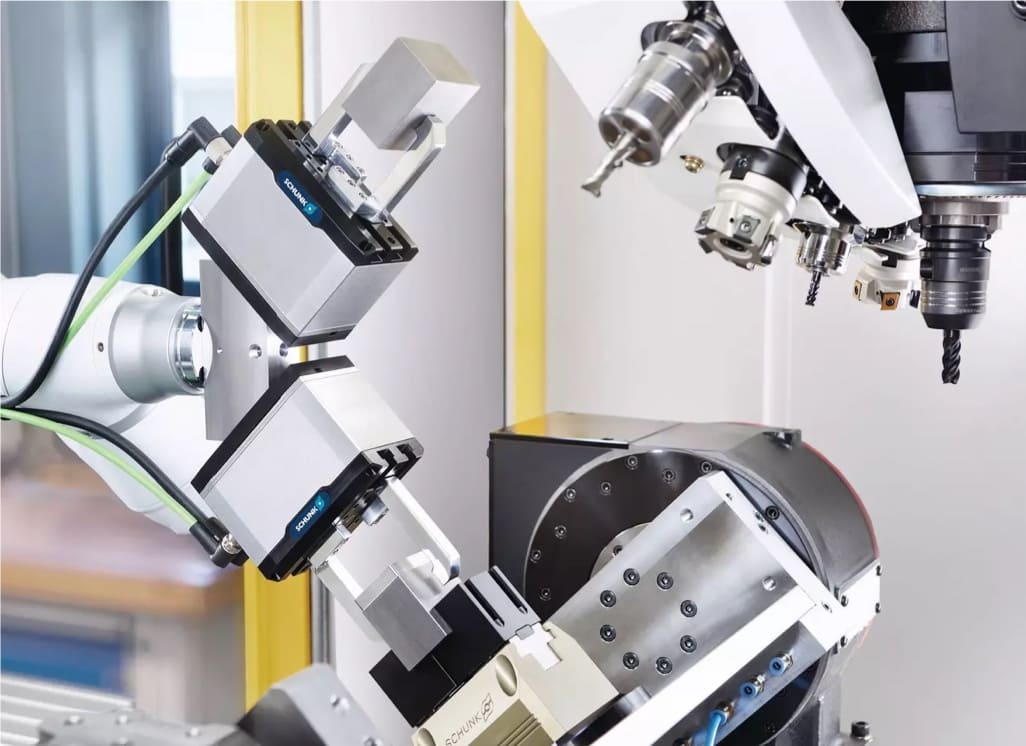

Motion Control & Automation

BEHCO is dedicated to helping our clients keep up with the ever-changing demands of automation with solutions tailored to their unique performance objectives and budgetary constraints. Our engineering team can help simplify your application and fulfill even the most complex system with our motion control solutions and components.

Industrial/Mobile Hydraulics Systems & Lubrication

With more than five decades of experience and access to a wide range of manufacturer components, BEHCO can serve your needs across industrial or mobile hydraulics systems and lubrication. Offering hydraulic power units, electro-hydraulic controls, manifold assemblies, lubrication and filtration systems, and more. When you work with BEHCO you can be confident that your solution is engineered and tested to address your specific application needs.

Safety, Sensors & Vision

Ensure the protection of your industrial operations with BEHCO's advanced safety, sensors, and vision solutions. Whether it be in manufacturing or logistics automation, our team's expertise guarantees effective process control that prioritizes safety for individuals and the environment. Count on our dedication to providing groundbreaking solutions customized to your automation requirements. With our knowledgeable team, you can expect full support for effortless integration and superior performance.

Pneumatics & Fluid Control

Where "off-the-shelf" pneumatic or fluid control solutions fail to deliver the optimal performance your system requires, BEHCO is your value-add partner. Our team brings expertise in electro-pneumatic panels and assemblies, air logic control systems, custom valve manifolds, air preparation assemblies, and more. Our in-house engineering and manufacturing teams will ensure your fluid control or pneumatic application needs are satisfied with a design that maximizes performance and efficiency.

Robotics & Vision

Automation is possible for companies of all sizes with endless opportunities for integrating robotics and vision into a variety of applications. Regardless of your industry, business size, or product type, we can improve and complement your current system by applying our extensive experience with collaborative robots and vision technology. Stay one step ahead of your competitors with solutions built with the future in mind.