BEHCO Automation Demo

The BEHCO dynamic automation team is revolutionizing and simplifying the possibilities for automation within small and medium-sized companies with robotics and vision technology that is accessible. These automation solutions are no longer out of reach and, in fact, are necessary to keep up with the demands of our ever-changing world.

If you’ve resigned yourself to manual production just because you’re not a big national manufacturer, or if you face low-volume, high-mix production, you no longer have to wonder if automation is possible.

BEHCO’s newest technical demonstration exhibits how companies of all sizes can achieve:

- Increased output

- Improved product quality

- Reduced costs

- ROI in <1 year

- Better, safer working conditions

- Business growth & profit!

Even complex automation challenges can be overcome with precision.

Create your dynamic automation experience.

BEHCO Automation DEMO: The Gift Giving Machine Automation Demo

As you witnessed in the live demonstration of the Gift Giving Machine, BECHO’s automation team has combined leading robotics and vision technologies to achieve an end-to-end solution handling random bin picking, part placement, inspection, track and trace, conveyance, and automation management.

In this case the entire process is controlled by Unitronics Controller and HMI, and the product lines mentioned below were used to engineer the Gift Giving Machine, but the possibilities are endless! Our BEHCO automation experts will design and build a solution tailored to your manufacturing needs3

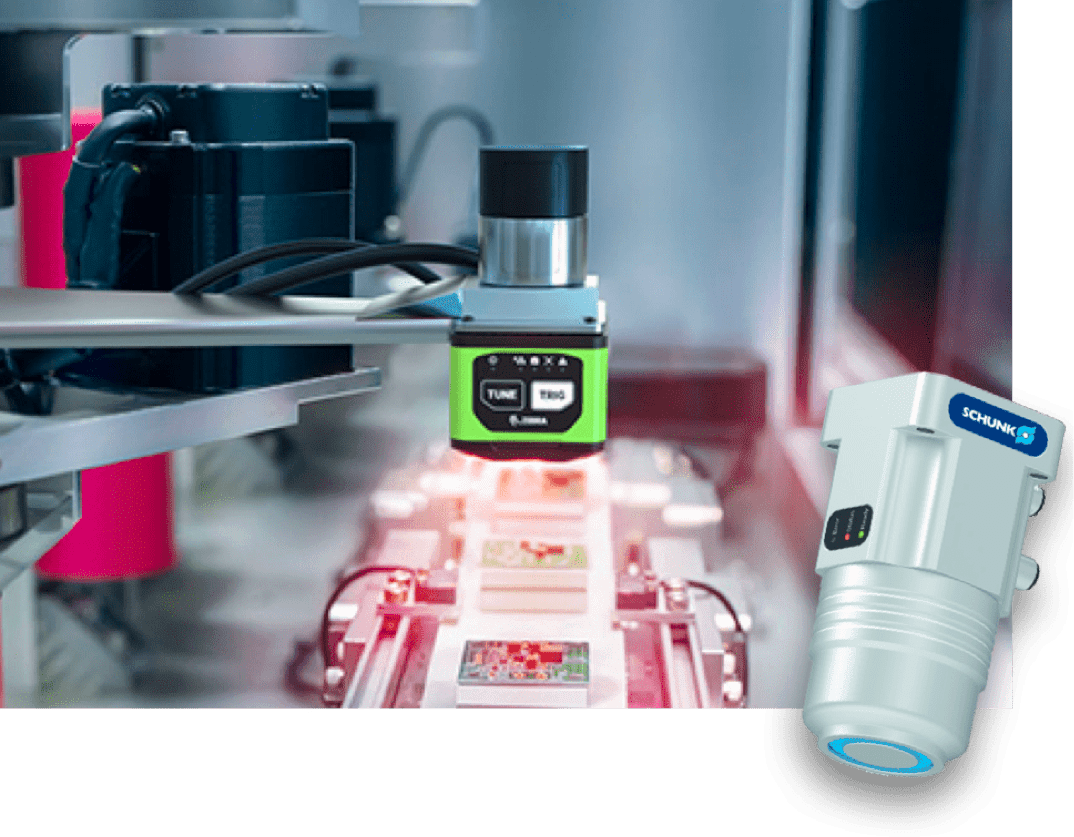

Where random part picking and placement is needed, BEHCO has made 3D random bin picking possible by combining Canon’s world class structured light sensor and software, Universal Robots’ UR5e collaborative robot, and Schunk’s magnetic gripper.

Then, by utilizing Zebra Technologies’ Fixed Scanning and Machine Vision cameras and Dorner conveyance solutions, BECHO can transform track and trace capabilities. In the demo, the Cobot presents the product to the Zebra cameras for inspection of quality, part accuracy, and label placement. Inspection takes place while the product is in transit, improving overall production efficiency. Upon approval, the product is then placed on the Dorner Conveyor and cycled to the end destination. With the demand traceability growing, manufacturers can now easily gain control, identify challenges at specific points within the process, and improve quality and accuracy.

Get your business on the fast track with Automation solutions that are:

- Built to resolve your specific challenges

- Cost effective

- Quick to deploy

- Low maintenance

- Flexible